As the main component of the new multi-nozzle opposed water-coal slurry pressurized gasifier, refractory materials are of great significance to the long-term stable operation of the gasifier. This paper analyzes the use conditions of refractory materials and proposes specific measures to extend the service life of refractory materials.

1 Working conditions of new gasifiers and the structure of refractory materials

1.1 Working conditions

The atmosphere in the multi-nozzle opposed water-coal slurry pressurized gasifier is highly reducing, with a CO+H2 content of generally more than 80%, containing only a small amount of CO2 and H2O, and may also contain trace amounts of H2S, NH3 and N2. The slag is usually acidic slag, that is, the content of SiO2 and Al2O3 in the slag is generally greater than the total amount of CaO and MgO alkaline slag.

1.2 Structure of refractory materials

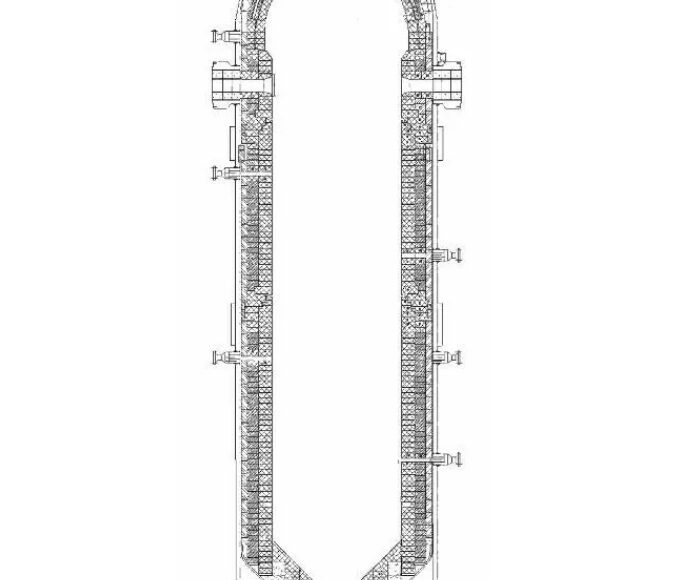

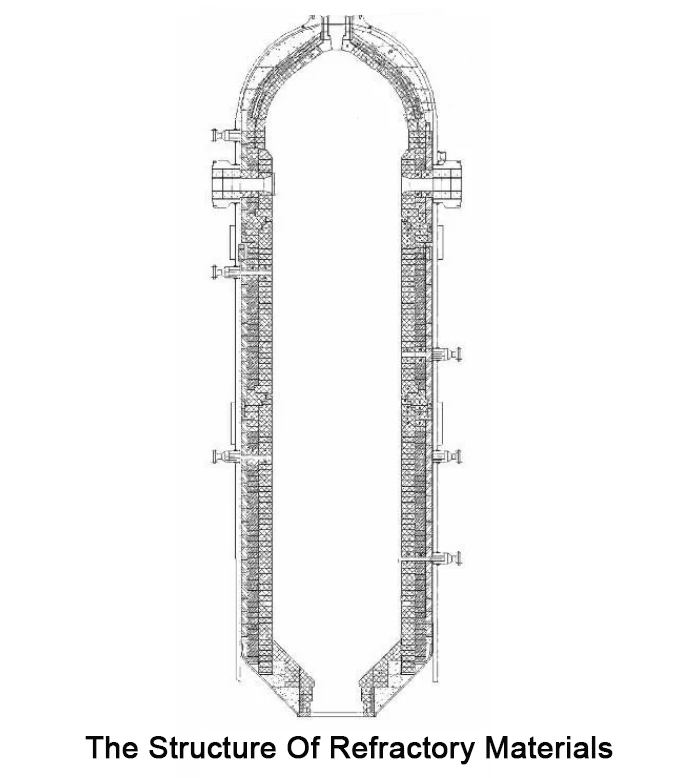

The lining refractory materials of the gasifier are divided into three layers, from the inside to the outside, they are high-chromium refractory materials, chromium corundum refractory materials, and alumina hollow spherical refractory materials (as shown in Figure 1). Among them, the high-chromium refractory bricks on the fire-facing surface are the most critical part to ensure the normal operation of the gasifier. The refractory material structure in the furnace consists of three parts from top to bottom: the dome, the cylinder, and the cone bottom. In order to facilitate the partial replacement of refractory bricks, the dome, the cylinder, and the cone bottom are designed to be replaced independently. The multi-nozzle opposed water-coal slurry pressurized gasifier is equipped with two brick support plates in the straight section of the furnace body, in order to reduce the cumulative dimensional deformation of the refractory material caused by temperature changes during use, and reduce the shearing effect on the burner, thermocouple and other components. A heat sink is provided on the outside of the furnace wall at the brick support plate position to enhance the heat dissipation effect of this part and prevent the furnace wall temperature from being too high at this location through the expansion joint.

2 Introduction to new gasifier refractory materials

2.1 Fire-facing refractory bricks

Since the fire-facing surface is in direct contact with coal slag, it is the most demanding part of the refractory material in the gasifier, so the fire-facing bricks are 90 high-chrome bricks. The raw materials used for high-chrome bricks are Cr2O3 electro-melted synthetic materials with a Cr2O3 content greater than 99 (bulk density greater than 5.1g/cm3), and ultra-fine powder is added. After mixing and molding, it is fired in a high-temperature shuttle kiln. This product has the advantages of high bulk density (greater than 4.40g/cm3), low porosity (less than 16%), high pressure resistance at room temperature (greater than 150Mpa), and low impurity content such as iron oxide and silicon oxide. At the same time, it has good thermal stability and high temperature creep resistance. These meet the requirements of refractory materials for the gasifier fire-facing surface, so 90 high-chrome bricks are currently the best choice for refractory materials for the gasifier fire-facing surface.

2.2 Backing bricks

Backing bricks are located behind the fire-facing bricks, playing an important mechanical support role for the gasifier refractory as a whole, and can withstand the erosion of corrosive gases at high temperatures. 12 chrome corundum bricks have high strength at room temperature (greater than 120Mpa), and the addition of more than 12% chromium oxide to high-purity corundum further increases the product’s resistance to corrosive gas erosion.

2.3 Insulation bricks

Insulation bricks are located behind the backing bricks, which play an insulation role for the gasifier, reduce heat loss, and keep the outer wall temperature at the set value. They are a good energy-saving material; in addition to low thermal conductivity (0.8W/mk/1000°C), alumina hollow ball bricks have the best strength at room temperature and high temperature among lightweight refractory materials, and have extremely low impurity content. They have good resistance to corrosive gas erosion and thermal stress buffering capabilities, and are currently the best lightweight insulation refractory materials.

2.4 Other auxiliary materials

2.4.1 Compressible layer

The compressible material has the characteristics of small bulk density and low thermal conductivity. It has good thermal insulation performance. At the same time, it has a certain strength, can effectively buffer the radial expansion of the inner layer of refractory materials under high temperature, and is very convenient to construct.

2.4.2 Refractory castables

(Chrome corundum castables, alumina hollow ball castables). Chrome corundum castables are used for arches and cone bottoms. Compared with bricks, castables have the following advantages: no mortar joints, that is, good integrity; convenient construction, especially the construction of complex structures, convenient, fast, labor-saving, time-saving and labor-saving. The castable has strong resistance to gas erosion. At the same time, because the volume density is greater than 3.20g/cm3, the castable has good airtightness. Alumina hollow ball castables have the advantages of thermal insulation, energy saving, and convenient construction, and are suitable for local use in gasifiers.

3 Ablation mode of refractory bricks

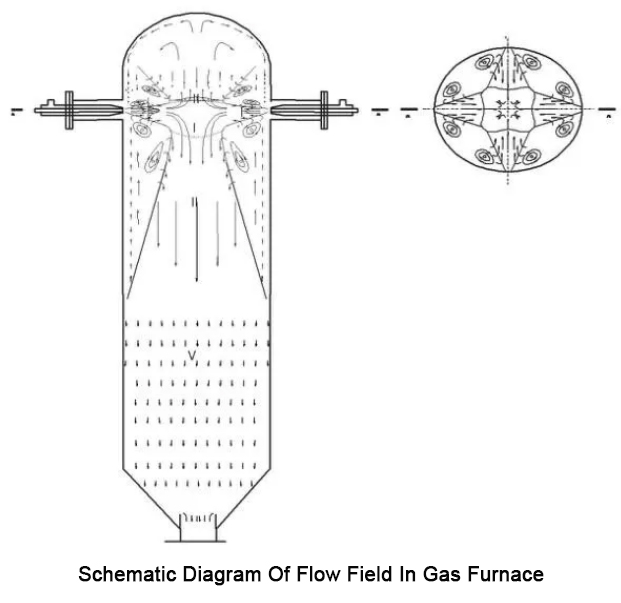

The temperature field and flow field in the gasifier are uneven, unstable, and even discontinuous (as shown in Figure 2). There are many reasons for the local high temperature. Therefore, it is easy for the surface of Cr2O3-Al2O3 refractory bricks to be damaged by high temperature and even cause local overburning and melting. Under normal circumstances, this ablation damage process is slow. Only under extremely abnormal high temperature and reaction conditions in the furnace will the ablation process be significantly accelerated. According to observation and analysis, the ablation of refractory bricks can be divided into high-temperature melting ablation and high-temperature redox ablation.

The high-temperature melting type ablation of refractory bricks in gasifiers mainly occurs in oxygen-rich areas, flame licking areas and over-oxygen conditions in gasifiers. These three areas/conditions are all local high-temperature areas in the gasifier. The main components of refractory bricks are Cr2O3 and A12O3, which are fired at high temperatures. Under normal temperature conditions in the furnace, they have good stability, and usually during operation, the surface of the refractory bricks is covered with molten slag, so the high-temperature airflow in the furnace will not directly contact the surface of the refractory bricks. However, in local oxygen-rich areas and areas where high-temperature airflow directly licks the surface of refractory bricks, the surface structure of the refractory bricks softens and the strength decreases, the wear and erosion resistance and the structure bonding performance decrease, and part of the bonding phase is directly burned. The rate of refractory brick burning is affected by many factors, such as gasifier working conditions, including oxygen-coal ratio, burner performance, slag mouth pressure difference, raw coal ash content, ash composition characteristics, vault brick shape and gasifier load, etc. At the same time, low melting point impurities in refractory bricks will also accelerate the melting and burning rate of refractory bricks.

4 Measures and precautions to extend the service life of refractory materials

The refractory materials of multi-nozzle opposed water-coal slurry pressurized gasifier are key materials to ensure the long-term stable operation of the gasifier. Extending the service life of refractory materials is an important task of gasifier operation management.

4.1. The influence of operating temperature on refractory erosion is very critical. The operating temperature should be strictly controlled during operation. Generally, the operating temperature is selected to be 50-80°C higher than the FT temperature of the coal ash melting point. Excessive temperature will cause severe damage to refractory bricks.

4.2. Strictly control the quality of masonry and heat up according to the furnace drying curve. The laying and baking of refractory bricks are an important link to ensure that the furnace body becomes a whole and prolong the service life.

4.3. By selecting and blending coal, the composition of slag is controlled. On the basis of ensuring the ash melting point, the content of Ca, Fe and Mg in the furnace coal is strictly controlled to reduce the corrosiveness of slag.

4.4. Stabilize various process indicators, extend the operation cycle of the gasifier, prevent sharp fluctuations in furnace temperature and sudden rise and fall of pressure, and reduce the damage of refractory materials caused by thermal shock stability.

5 Conclusion

The new multi-nozzle opposed water-coal slurry pressurized coal gasification technology has become increasingly mature. With the improvement of the refractory process environment, the application of refractory materials has reached a relatively ideal cycle, laying a solid foundation for the promotion of new coal gasification technology.