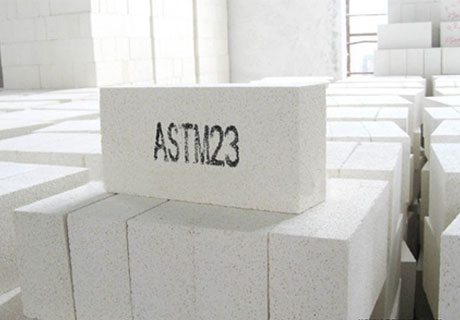

Refractory Bricks, an excellent kiln furnace refractory material, is briefly called kiln fire brick that has certain shapes and sizes. Refractory brick includes different types of burnt brick, unburned brick, fused cast brick and refractory insulating brick according to different manufacturing processes. Refractory bricks can be used as high temperature building and structure materials for kiln furnace and all kinds of heating equipment to resist all kinds of physical chemistry changes and mechanical action.

Refractory Bricks are quality refractory materials with various excellent performance of high temperature resistance, slag and wear erosion resistance, compressive strength, thermal shock resistance and etc., and can be used in many industries fields of metallurgy, chemical engineering, petroleum, machinery manufacturing, power such as blast furnace, rotary kiln, cement kiln, glass furnace, hot blast stove, coke oven, power boilers, boiler and so on.

Type: Silicon Carbide Mullite Brick, Corundum Mullite Brick; Zircon Mullite Brick

Property: High refractoriness, Good thermal shock resistance,Strong acid erosion resistance, Great wear resistance, Low thermal expansion coefficient & High thermal conductivity

Application: Basic open-hearth furnace for steel making, Electric furnace bottom and wall, Permanent lining of oxygen converter,Non-ferrous metal metallurgy furnace

Note: Any Interests for our Mullite brick, emial us for quotation & more information:inquiry@rsrefractorygroup.com

Type: Magnesia Carbon Brick, Magnesia Chorme Brick and Fused Magnesia Brick,Magnesia Zirconia Brick

Property: High refractoriness, Good alkaline slag erosion resistance, High apparent initial softening temperature, Good thermal conductivity & High thermal expansion

Application: Basic open-hearth furnace for steel making, Electric furnace bottom and wall, Permanent lining of oxygen converter,Non-ferrous metal metallurgy furnace,Lining of rotary cement kiln, Regenerative chamber of glass furnace

Note: Any Interests for our Magnesia brick, emial us for quotation & more information:inquiry@rsrefractorygroup.com

Type: Fused Cast AZS33, Fused Cast AZS36 and Fused Cast AZS41

Property: Dense micro structure,Strong resistance for high temperature and glass liquid, Good thermal shock resistance,High compression resistance & Wear and slag erosion resistance

Application:superstructure, paving blocks, feeder channels, tank bottoms, working pool side wall, C-shaped block side walls, working layer and doghouse crown in glass furnace.

Note: Any Interests for our Fused Cast AZS brick, emial us for quotation & more information:inquiry@rsrefractorygroup.com

Type: Fused Corundum Brick; Chrome Corundum Brick; Corundum Mullite Brick

Property:Low thermal conductivity,Good thermal insulation performance,High thermal shock resistance,Great abrasion resistance,Excellent chemical erosion resistance

Application:Used for secondary position in coke oven such as protection wall of regenerative chamber, lining brick of sole flue, furnace door, furnace top and ascension pipe.

Note: Any Interests for our Corundum brick, emial us for quotation & more information:inquiry@rsrefractorygroup.com

Type: High Alumina Brick, Alumina Carbon Brick; High Alumina Refractory Ball; Alumina Bubble Brick

Property: High temperature resistance,Good chemical erosion resistant, Goood thermal stability and slag resistance, Corrosion-resistant, Various shapes and high quality

Application:industries of blast furnace, hot blast stove, electric furnace, refining furnace and glass furnace

Note: Any Interests for our Alumina brick, emial us for quotation & more information:inquiry@rsrefractorygroup.com

Type: Silica brick,Sillimanite brick; Alumina Silica Brick

Property: Acid-base Resistance, Expansibility, Refractoriness Under Load, Thermal Stability

Application:lay coking chamber of coke oven and partition wall of combustor, kiln crown and wall of glass furnace and calcining kiln of silicate product.

Note: Any Interests for our Silica brick, emial us for quotation & more information:inquiry@rsrefractorygroup.com

Type: Resistance clay brick,Low creep clay brick,Arched clay brick,Carbon furnace clay brick

Property: High temperature resistance,Good chemical erosion resistant, Goood thermal stability and slag resistance, Corrosion-resistant, Various shapes and high quality

Application:industries of blast furnace, hot blast stove, electric furnace, refining furnace and glass furnace

Note: Any Interests for our Fire Clay brick, emial us for quotation & more information:inquiry@rsrefractorygroup.com

Rongsheng Refractory Brick Application

We Rongsheng Company are able to supply all kinds of refractory bricks (also including other refractory material) that widely are used in Steel Industry, Petrochemical Industry, Metallurgy Industry, Noferrous Industry and Building Industry and suitable for different Furnace/Kiln, such as Glass Kiln, Tundish Furnace, Steel Casting Lable, Cement Kiln, Electric Arc Furnace ,Torpedo Ladle and other various Furnace. If you have interests for our refractory brick and kindly tell which furnace you are using, then our professional engineer will design the drawing with recommended suitable bricks in every part of your furnace/ kiln.

Glass Furnace

Tundish Furnace

Steel Casting Ladle

Cement Kiln

Electric Arc Furnace

Torpedo Ladle

Rongsheng Refractory Brick Manufacture Lining

The initial step in producing brick is crushing and grinding the raw materials in a separator and a jaw crusher. Next, the blend of ingredients desired for each particular batch is selected and filtered before being sent on to one of three brick shaping processes—extrusion, molding, or pressing, the first of which is the most adaptable and thus the most common. Once the bricks are formed and any subsequent procedures performed, they are dried to remove excess moisture that might otherwise cause cracking during the ensuing firing process. Next, they are fired in ovens and then cooled. Finally, they are dehacked—automatically stacked, wrapped with steel bands, and padded with plastic corner protectors.

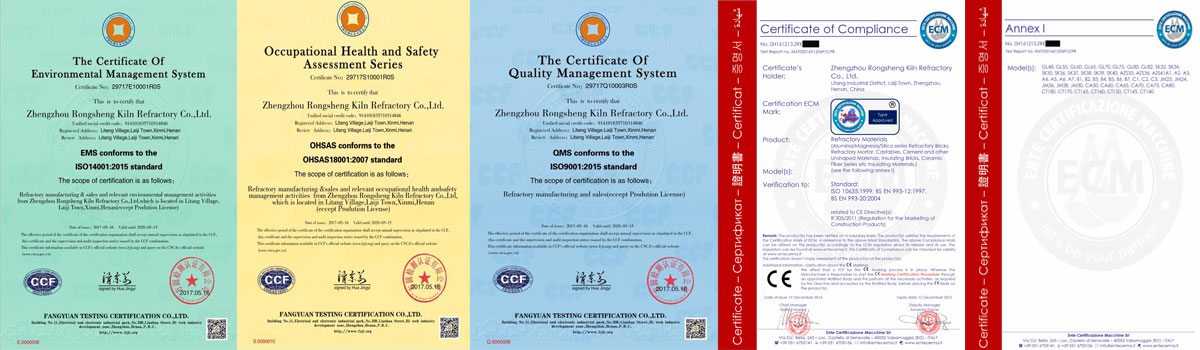

Quality Certification of Rong Sheng Company

Rongsheng Refractory has established complete quality system and conducted quality control through the whole staff and process that from raw materials, production, check and various parts strictly according to ISO9001 standard and with the professional checker at each level to take good product and service as the top goal.We have passed through the certification authority, provide more protect for you. If you also need other Special products certification, please contact us, we are glad to help you make the special approval for you.

Clients Visiting our factory

We rongsheng kiln refractory material group is the leading manufacturer and supplier in China, which have manufactured the refractory products for over 20 years experience, every year, Many clients all over the world come to China for visiting and checking our refractory products and factory to assure the quality and service, if you also have the plan to visit the factory, pls kindly contact us, we will arrange the hotel in advance and pick you up from the airport station or train station, even free invitation letter also will be help for you, if you need.

Why choose Rongsheng as supplier

1. Professional Design Service, if you tell your kiln situation, we can advice you the most suitable refractory brick for every parts of your kiln/Furnace

2. We supply various refractory Bricks and Various fire brick also can be customized by your exact Kiln/furnace and at your request.

3. Professional Manufacturer and supplier, Over 20 years producing experience, over 8000 square meters area.

4. Free Sample Avaiable, Sometimes also with free package and shipping.

5. All of our refractory products meet national standard by strict quality control, Provide various quality certificate.

6. Fast Delivery, by reputed shipping line and professional documents.