The main function of the thermal insulation brick is to keep warm and reduce the loss of heat. The thermal insulation brick generally does not directly contact the flame, and the refractory brick generally contacts the flame directly. Refractory bricks are mainly used to withstand the flame roasting. Generally divided into two types, namely, amorphous refractory materials and shaped refractories.

Unshaped refractory: also known as castable, is a mixed powdery granule composed of a variety of aggregates or aggregates and one or more binders. It must be mixed with one or more liquids evenly when used. Has a strong liquidity.

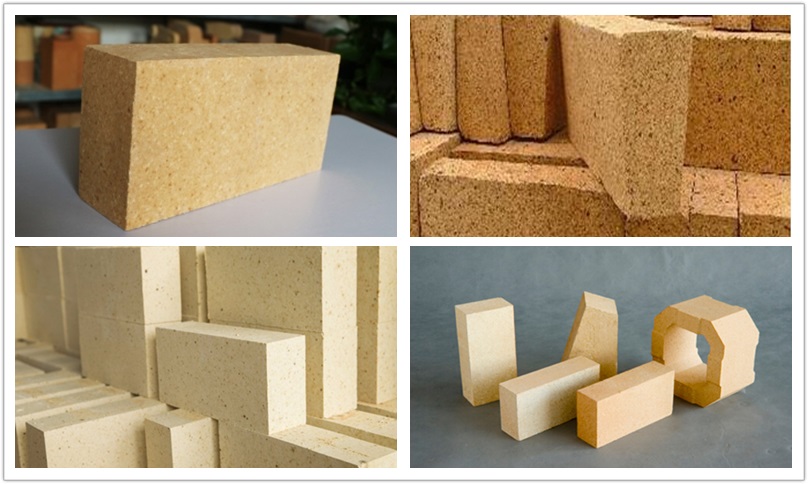

Shaped refractory: General refractory bricks, which have standard rules in shape, and can be temporarily processed as needed.

The main differences between insulation bricks and refractory bricks are as follows:

1. Insulation performance

The thermal conductivity of the insulating brick is generally 0.2-0.4 (average temperature 350±25°C) w/mk, and the thermal conductivity of the refractory brick is 1.0 (average temperature 350±25°C) w/mk or more, thus the insulating brick can be obtained The insulation performance is much better than that of refractory bricks.

2. Refractoriness

The refractoriness of the insulating brick is generally below 1400 degrees, while the refractory brick has a refractoriness of more than 1400 degrees.

3. Density

Insulation bricks are generally lightweight insulation materials, the density is generally 0.8-1.0g/cm3 and the density of refractory bricks is basically above 2.0g/cm3.

In general, refractory bricks have high mechanical strength, long service life, good chemical stability, no chemical reaction with materials and high temperature resistance, and high heat resistance temperature can reach 1900 °C. It is especially suitable for high and low temperature shifting furnaces, reforming furnaces, hydroconverters, desulfurization tanks and methanation furnaces in fertilizer plants. It acts to disperse gas and liquid, and to support, cover and protect the catalyst. It can also be used in hot air furnaces and heating converters in the steel industry.

The refractory brick has the advantages of high density, high strength, good wear resistance, good corrosion resistance, small thermal expansion coefficient, high grinding efficiency, low noise, long service life and no contamination of materials. It is a high-quality grinding medium suitable for various grinding machines.

Refractory bricks are very different from insulating bricks, and their environment, scope and function are different. Different materials will be used in different locations. When purchasing materials, we should decide which refractory material is suitable for our own use according to our actual situation.