Recently, Zhengzhou Rongsheng Refractory Co., Ltd. completed the “technical research and development and industrial application of aluminum chromium monolithic refractory materials for plasma incinerators”, “aluminum titanate-mullite high thermal shock refractory materials for kiln furniture” The two projects of “Technology R&D and Industrial Application” successfully passed the scientific and technological achievement evaluation of Henan Zhiqi Achievement Evaluation Center. The evaluation committee believes that the project results have independent intellectual property rights, the technology is difficult and innovative, and the overall technology has reached the domestic leading level.

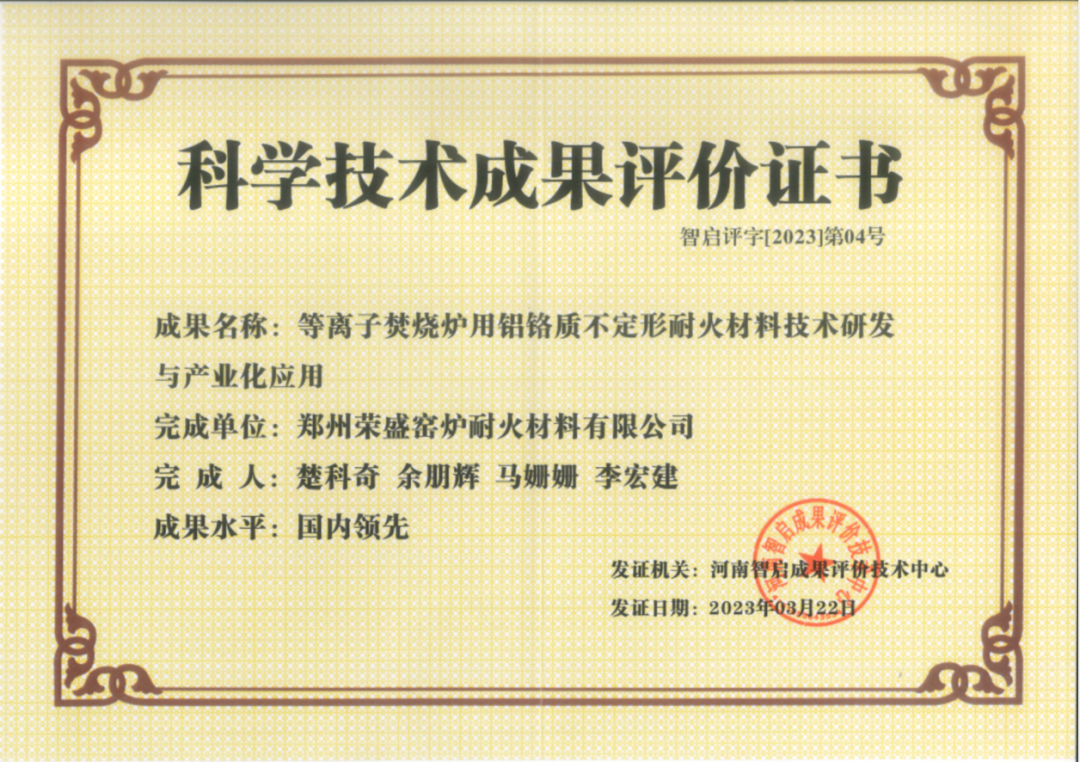

Aluminum chromium monolithic refractories for plasma incinerator

Technology research and development and industrial application

This technology adopts the hot gunning technology, which is directly sprayed on the surface of the aluminum-chrome brick to protect the aluminum-chrome brick in the working layer of the furnace wall from further erosion, greatly prolonging the service life of the refractory material in the working layer and improving the efficiency of the plasma incinerator. work rate. It has the characteristics of high bonding strength with the original brick lining refractory material, wear resistance, shock resistance, peeling resistance, firmness and durability, construction is not affected by seasonal climate and temperature, and is fast and convenient. The main innovations are as follows: 1. Using corundum and chromium oxide micropowder as the main raw materials, the aluminum chromium monolithic refractory has the characteristics of excellent corrosion resistance, strong slag resistance, small expansion coefficient, low creep, and anti-stripping. 2. A new type of composite binder is adopted, which makes the material have good adhesion performance, low rebound rate, and reduces the loss of materials during construction. At the same time, it is ensured that the aluminum-chromium monolithic refractory material has a relatively high melting point during use, and that the aluminum-chromium monolithic refractory material does not peel or peel off during the heating process.

The technical achievements of this project have comprehensively improved the service life of the refractories in the working layer of the kiln, ensured the operating rate of the plasma incinerator, and achieved a breakthrough in the quality of gunning materials for domestic plasma gasifiers. The material aspect is a very important addition.

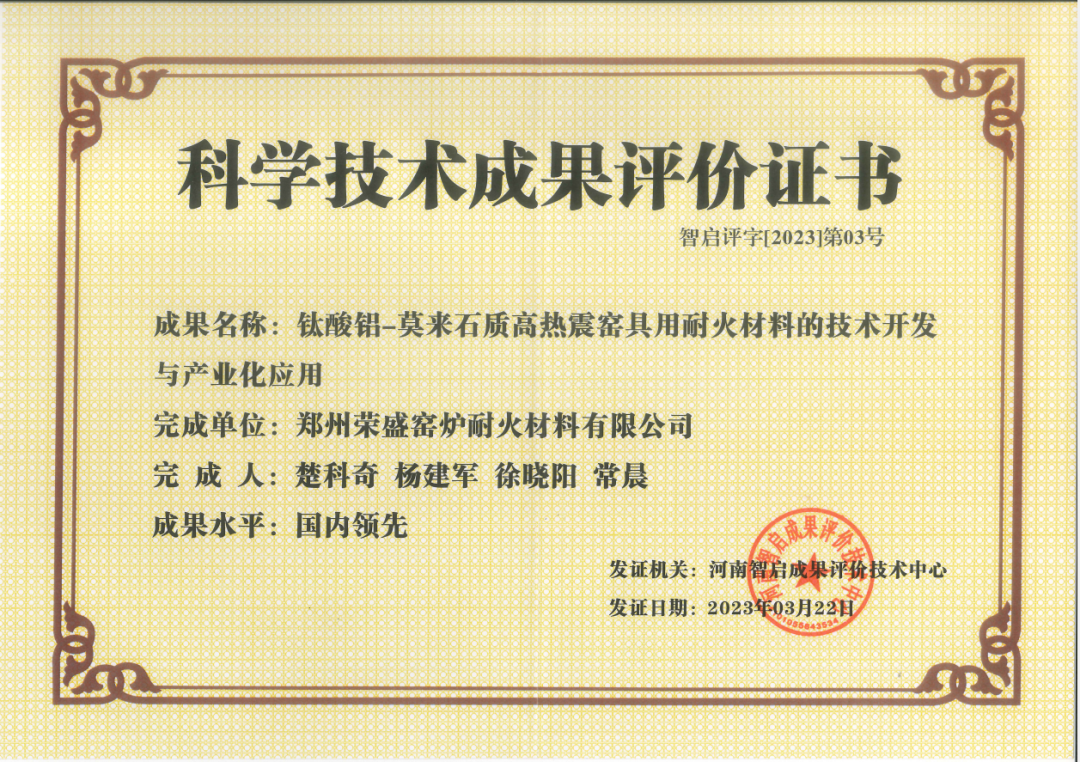

Aluminum titanate-mullite refractory material for high thermal shock kiln furniture

Technology research and development and industrial application

This technology adopts stabilized aluminum titanate-mullite composite material with excellent synthetic performance, and uses this raw material to prepare kiln furniture with good performance, which greatly improves the thermal shock resistance of the material, and has high strength and Good thermal shock resistance, thus improving the service life of refractory materials for kiln furniture. The main innovation point is: using mullite and iron oxide to inhibit the decomposition of aluminum titanate, thereby improving the strength and thermal shock resistance of refractory materials for kiln furniture, and achieving the effect of increasing the service life.

The technical achievements of this project have comprehensively improved the service life of high-grade refractory materials used in kiln furniture, ensured the long-term operation of ceramic industrial kilns, and realized the industrial application of domestic aluminum titanate-mullite refractory materials in kiln furniture products. It breaks the long-term dependence on imports of high-grade refractory materials for kiln furniture, has important social and economic benefits, and has broad market application prospects.