The working temperature of the hydrogen sulfide combustion incinerator is about 1150°C, and the working conditions are harsh. It belongs to an acidic combustion atmosphere, but in actual production, due to the fluctuation of materials and air volume, the furnace temperature will reach 1400°C. The amount of hydrogen sulfide gas is very unstable, and every combustion fluctuation in the furnace is a great thermal shock to the furnace lining.

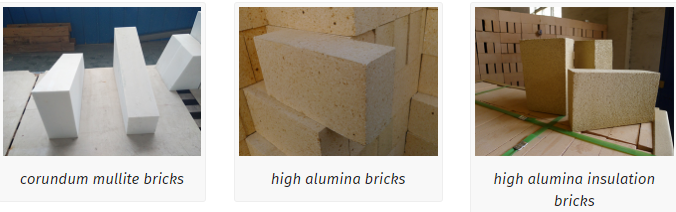

And this sour gas furnace liner is made of refractory materials, so acid corrosion resistance and thermal shock stability are very important. The main body of the furnace can adopt a three-layer structure. The parts in direct contact with the flame should use corundum mullite bricks. It is characterized by strong wear resistance and corrosion resistance. The interlayer can choose three grades of high alumina bricks. Since the working layer is not directly in contact with the flame, the flexibility of the three-grade high-alumina brick is relatively good. The outer layer can be used as an insulation layer, and high-alumina heat-insulating refractory bricks are used to cool and reduce the temperature of the outer wall of the steel shell.

Corundum mullite brick is a refractory product composed of mullite as the main crystal phase and corundum phase and fired at a high temperature of 1650-1750 °C. It has good high temperature resistance, high temperature creep resistance, thermal shock resistance and corrosion resistance.

The third-grade high-alumina bricks are a series of aluminum products fired at 1400°C with high-alumina raw materials and clay as a binder. High thermal stability, strong flexibility.

Lightweight brick with high alumina content. It has the characteristics of low bulk density, large porosity, low thermal conductivity, and large specific heat capacity. The insulation layer has good insulation performance. In the case of slow heat dissipation, it can save fuel and reduce the temperature of the steel shell.

The hydrogen sulfide combustion incinerator is one of the few furnace types, so the corundum mullite brick used in the refractory lining for its refractory lining is a high-quality refractory material. High-alumina bricks are neutral materials, and lightweight high-alumina bricks are used as the three-layer masonry lining to effectively improve the corrosion resistance of the incinerator. The refractory mortar of the same material is used for masonry during construction to ensure the long-term safe and reliable operation of the incinerator.