Abstract: The safe disposal of hazardous waste has always been a concern. The combustion system of the rotary kiln is introduced. The typical hazardous waste treatment process, through engineering examples, shows that the rapid cooling tower, dry reactor, bag dust removal, and scrubber combined process combustion flue gas can achieve pollutant emission standards. Incineration can effectively destroy toxic, harmful and organic wastes in wastes, and is the fastest and most effective technology to achieve the reduction of hazardous wastes and harmless. Incineration treatment is suitable for hazardous wastes, not suitable for recovering its useful components, and has a certain calorific value. After more than 20 years of development, the treatment of hazardous waste incineration technology abroad has become quite mature, and can be used for the treatment of industrial hazardous waste incinerators: rotary kiln incinerators, liquid jet incinerators, pyrolysis incinerators, fluidized bed incinerators, multi-layer incinerators and other types of furnaces. Among them, the rotary kiln incinerator is the mainstream furnace used to incinerate industrial hazardous wastes. Regarding the specific situation of hazardous waste disposal in my country, the government encourages local governments to give priority to the use of rotary kiln-based incineration technology.

Preface: In recent years, the technology of solid waste co-treatment in cement kilns has been surging, and many traditional cement production enterprises have been involved in solid waste treatment. In order to regulate the pollution prevention and control of solid waste co-treatment in cement kilns, the state has formulated relevant standards and policies: HJ662-2013 “Technical Specifications for Environmental Protection of Solid Waste Co-treatment in Cement Kilns”, GB30485-2013 “Pollution Control Standards for Solid Waste Co-treatment in Cement Kilns”, “Technical Policy for Pollution Prevention and Control in Cement Industry” (Announcement No. 31 of the Ministry of Environmental Protection in 2013), “Evaluation Index System for Clean Production in Cement Industry” (Announcement No. 3 of the Development and Reform Commission in 2014), GB30760-2014 “Technical Specifications for Solid Waste Co-treatment in Cement Kilns”, “Technical Policy for Pollution Prevention and Control of Solid Waste Co-treatment in Cement Kilns” (issued by the Ministry of Environmental Protection in 2017). The new technologies that the policy encourages to develop include: pollutant emission reduction technology in the production process of cement kilns that co-dispose of solid waste; efficient utilization technology of cement kilns that increase the amount of co-disposal of solid waste, such as large-volume solid waste offline combustion systems; efficient pretreatment technology for co-disposal of solid waste, such as high-quality refuse-derived fuel (RDF) preparation technology. Co-disposal of domestic waste by cement kilns is one of the advanced methods for domestic waste treatment. Different processes have different probabilities and amounts of dioxin generation, and different processes also have different moisture content of garbage entering the furnace, calorific value of incineration gas (or pyrolysis gas), ignition start-up methods, heat carrier entry temperature, slag cooling methods, and heat utilization efficiency. Correctly analyzing the advantages and disadvantages of various processes will help improve the technical level of cement kilns for co-disposal of domestic waste and promote the development of this technology.

1. Rotary kiln incineration system

1.1 Basic Principles

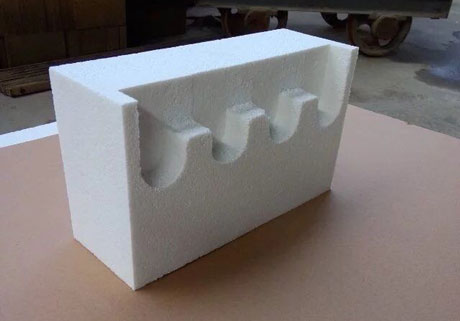

The rotary kiln incinerator, also known as the rotary kiln, evolved from the cement rotary kiln. The main body is a rotatable horizontal cylindrical shell made of steel plate and lined with refractory material. The axis of the pipe and the water level are protected. There is a certain inclination, and solid and semi-solid waste enters the kiln from the high end (head) through the feeder, and slowly moves to the tail as the cylinder rotates. The rotation of the kiln body makes the material fully contact with the combustion air during the combustion process, completing the entire process of drying, combustion, combustion, cylinder body, entering the combustion chamber and fuel slag characteristics, and discharged by the aircraft ash and slag. According to the different flow directions of furnace gas and solid, or the position of the heat source (burner) in the rotary kiln, the rotary kiln can be divided into upstream and downstream forms, which are preserved in the forward direction of the rotary kiln. The flue gas flow is the same, also known as countercurrent. The design of the rotary kiln is suitable for feeding and pretreatment, which can increase the time of flue gas and is widely used in hazardous waste incineration systems. Countercurrent rotary kilns are more suitable for hazardous wastes with high moisture content or low calorific value (such as sludge).

1.2 Typical Process

The rotary kiln incinerator has a wide range of material applicability and can simultaneously process solid, liquid and gaseous hazardous wastes. The rotary kiln is a hollow steel cylinder with a slightly inclined lining and refractory bricks, usually very long. Various types of hazardous wastes that have been pretreated and compatible enter the combustion system through different feeding methods. Under the driving force of its own gravity and the continuous rotation of the rotary kiln, the furnace body turns over and fully contacts the combustion air to complete the drying (water evaporation), gasification and combustion processes. Finally, the remaining preheater becomes slag, and the slag is continuously discharged through the water seal machine.

2. Analysis and discussion of key equipment

2.1 Vertical incinerator

The vertical incinerator is a furnace type developed based on the traditional vertical furnace and suitable for waste incineration. The vertical incinerator has the characteristics of simple structure, convenient operation and moderate processing capacity, and has been applied in the cement kiln co-processing domestic waste process. It adopts the operation mode of upper feeding, lower discharging, upper gas outlet, and lower (or waist) oxygen supply and combustion. It is one of the most basic traditional calciner types. The main function of a vertical incinerator is combustion or incineration. The organic ash after burning or incineration of domestic waste directly enters the cement kiln system with the incineration gas, and the volume of inorganic slag is less than 5% of the original waste volume. The solid objects in the inorganic slag are metals, ceramic flakes, bricks, glass, etc. The metal objects are sorted and recycled; the remaining inorganic slag is sorted and used as cement raw materials; the combustion of organic matter produces high-temperature flue gas, dust and incineration gas containing calorific value. To the cement kiln’s precalciner to provide heat and degrade dioxins.

2.2 Rotary pyrolysis furnace

The rotary pyrolysis furnace is a waste pyrolysis furnace type developed on the basis of the ATP furnace and Gallet furnace in the oil sand and oil shale refining industry based on the common technology of the rotary kiln. Different from the conventional rotary kiln used for calcination, the pyrolysis furnace mixes the solid heat carrier heated to a higher temperature (around 650°C) with the normal-temperature garbage at the feed end of the pyrolysis furnace to transfer the heat to the garbage, so that the garbage can be processed without any fuss. The pyrolysis temperature (400~450℃) is reached in the state of oxygen or low oxygen, and pyrolysis gas and slag with very little dioxin content are generated. The slag continues to be heated to a higher temperature (650~750°C) at the kiln head (discharge end), and then is screened in the furnace, and part of the high-temperature fine slag is sent to the feed end of the kiln head again to be mixed with garbage for pyrolysis. Part of the pyrolysis gas is used as fuel to provide heat for the pyrolysis furnace; the excess pyrolysis gas is sent as fuel to the cement kiln precalciner and degraded in the precalciner. The pyrolysis gas at the heating end of the pyrolysis furnace is burned to produce high-temperature flue gas (above 800°C) with less oxygen content. The heat is also transferred to the garbage during the flow from the kiln head to the kiln end, which also achieves the effect of pyrolysis. The approach to garbage pyrolysis is based on the above-mentioned solid heat carrier method and high-temperature flue gas contact method. During the entire pyrolysis process, the probability of waste coming into contact with oxygen is minimal, so the amount of dioxin produced is also small.

2.3 Dryer

The heat source of the garbage dryer comes from part or all of the high-temperature exhaust gas (about 250°C) of the grate cooler. Whether it is a grate dryer or a rotary dryer, the average temperature of the garbage in the dryer is around 150°C. The drying gas is used in the grate cooler as cooling gas and finally enters the kiln, so that the waste heat of the drying gas can be rationally utilized.

3. Analysis and discussion of key processes

3.1 Furnace type and dioxin generation

The functional difference between pyrolysis furnaces and vertical incinerators is pyrolysis and incineration. Although the final inorganic slag produced is basically the same, the pyrolysis and combustion mechanisms are essentially different. The former is a chemical decomposition process in which organic matter is heated in an oxygen-free or anoxic state to crack the high molecular hydrocarbon chain into a mixture of gas, medium molecular fuel and carbon black, which is mainly low molecular hydrocarbons. The latter is a chemical decomposition process of hydrocarbons. The oxidation exothermic reaction of compounds under aerobic or oxygen-rich conditions produces CO2 and H2O. The incineration method easily produces large amounts of dioxins and furans, and dioxins are one of the most toxic organic compounds in the world. The oxidation reaction of combustion and the chlorine in plastic products are the environmental conditions for the generation of dioxin. Although high temperatures above 800°C can decompose most dioxin, the hot active atoms of heavy metals in combustion become catalysts for the reduction of dioxin. Dioxins are regenerated in a temperature environment of 300~500℃. Garbage pyrolysis is a process in which garbage is heated to high temperatures to thermally crack it in an oxygen-free or hypoxic environment. Waste pyrolysis not only eliminates the conditions for oxidation reaction, but also reduces the production of dioxin precursors, fundamentally inhibiting the production of dioxin. Since heavy metals in garbage do not have the conditions for high-temperature oxidation, it is difficult to generate catalysts that promote the generation of dioxin. Therefore, it can be said that the generation of dioxin can be eliminated from the source.

3.2 Oxygen consumption

The amount of CO2 produced in the vertical incinerator co-processing process is not dried and dehydrated before incineration, and the moisture content is about 20% (moisture content is higher in summer). It even needs to be mixed with an appropriate amount of coal in the waste before it can be incinerated. Therefore, waste disposal without pre-drying will generate a high amount of CO2. At the same time, due to the high water content of the garbage, the calorific value of the incineration gas is low. The calorific value of the incineration gas is lower than 3500kJ/Nm3, which has a certain impact on the stability of the decomposition furnace.

Conclusion: In recent years, as the country has strengthened its supervision of hazardous wastes. Large-scale rotary kiln incineration technology will be more widely used in hazardous waste treatment.