Description of Alumina Bubble Brick

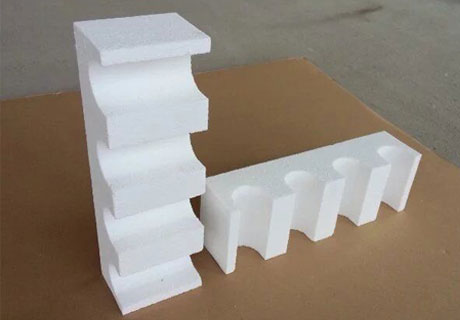

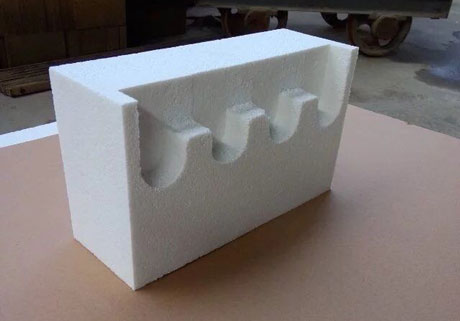

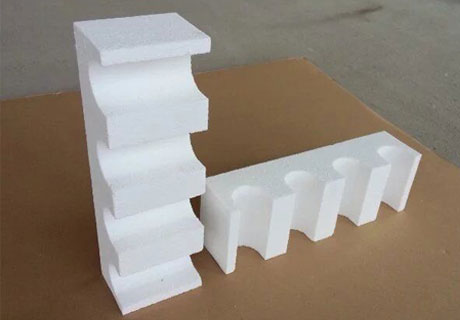

Alumina Bubble Brick use Alumina Bubble balls as the main raw material, high-performance powders as additives, organic materials as temporary bonding agents, and are fired at high temperatures in a shuttle kiln. The product contains a large number of closed air holes, which are characterized by light weight and high temperature resistance, good heat preservation performance, small re-calcination shrinkage, excellent thermal shock resistance, and strong resistance to aggressive gases and slag.

Alumina Bubble Brick is a new type high temperature heating insulation materials and made of industrial alumina in the electrical furnace through smelting and blowing. Alumina Bubble Bricks’ crystal form is a-Al2O3 microcrystal and main body is alumina bubble that can be made to be all kinds of products with various shapes for serving the highest temperature of 1800℃ with high mechanical strength and low bulk density.

Performance of Alumina Bubble Brick

1.high temperature using: Can be up to 1750℃, good thermal stability, re-scalding line rate and durable use.

2.optimize the structure, reduce the weight of the furnace: commonly used high-temperature materials are heavy bricks, the bulk density is generally 2.6-3.0g/cm, while the Alumina Bubble Brick is only 1.1-1.5g/cm, the same 1M3 volume, the use of oxidation Alumina Bubble Brick can reduce the weight of 1.1-1.9 tons.

3. saving materials: For the same temperature price, If Using the Alumina Bubble brick, per cubic meter can save the use of 1.1-1.9 tons of heavy bricks, but also save 80% of fire-resistant insulation material.

4.Energy Saving effect can reach more than 30%: Alumina Bubble Brick have obvious thermal insulation properties and low thermal conductivity, which result in good thermal insulation effect, By reducing heat dissipation, and increasing thermal efficiency, thus saving energy.

Technical Specifications of Alumina Bubble Brick

| Item | Alumina Bubble Brick | ||

| Grade | AKZ-85 | AKZ-90 | AKZ-99 |

| Al2O3 | ≥85 | ≥90 | ≥99 |

| SiO2 | ≤13 | ≤8 | ≤0.2 |

| Fe2o3 | ≤0.5 | ≤0.5 | ≤0.5 |

| Refractoriness℃ | 1750 | 1770 | 1790 |

| Apparent Porosity % | 58-62 | 58-62 | 58-62 |

| Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 |

| Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 |

| 0.2Mpa RefractorinessUnder Load T0.6℃ | ≥1650 | ≥1700 | ≥1700 |

| Permanent Linear Change On Reheating % 1500℃X2h | ±0.3 | ±0.3 | ±0.3 |

| 20-1300℃ Thermal Expansion % x 10-6 | 0-7.8 | 0-8.0 | 0-8.6 |

| Thermal Conductivity Average 800℃ W/m.k | ≤0.8 | ≤1.3 | ≤1.5 |

| Max Service Temperature ℃ | 1680 | 1700 | 1800 |

Applications of Alumina Bubble Brick

Alumina Bubble Brick can be used for high-temperature energy saving (>30%) down-draft kiln, shuttle kiln, molybdenum furnace, tungsten rod furnace, induction furnace, nitriding furnace and so on. For reducing the weight of the furnace body, renovating the structure, saving materials, and saving energy, significant results will be achieved. It has been widely used in petrochemical industrial gasifiers, carbon black industrial reactors, metallurgical industrial induction furnaces and other high-temperature, ultra-high temperature furnaces.