Zirconium silicate is an important ceramic raw material, which occupies an important position in ceramic production. Zirconium silicate has excellent properties, such as high melting point, low thermal conductivity, good chemical stability and corrosion resistance, which make zirconium silicate an important raw material in the manufacturing process of ceramic products.

The process of making zirconium silicate is actually very simple. First, zircon sand, silicate solution and caustic soda solution need to be mixed together in a certain proportion. Then, through high-temperature roasting, these mixtures are chemically reacted at high temperature to produce zirconium silicate. This process sounds complicated, but it is actually not difficult to operate.

In ceramic production, zirconium silicate is often used as an additive to improve the performance of ceramic products. It can not only be used as a flux, but also improve the appearance and internal quality of ceramic products. For example, in the production of high-end ceramic tableware, zirconium silicate can be used to improve the light transmittance and strength of the product, while also improving the surface smoothness and wear resistance of the product.

First, it can be used as a permeability enhancer for ceramics. Applying a layer of zirconium silicate on the surface of ceramics can make the surface of ceramics smoother and light easier to penetrate, thereby improving the light transmittance of ceramics. Secondly, zirconium silicate can also enhance the high temperature resistance of ceramics. Since zirconium silicate itself has a high melting point, ceramics with zirconium silicate added can be used at higher temperatures. In addition, zirconium silicate can also improve the mechanical strength and insulation properties of ceramics.

In addition, zirconium silicate can also be used to produce glazes. Glaze is a thin layer of glass applied to the surface of ceramics, which can improve the appearance and performance of ceramic products. Zirconium silicate can be used in combination with other raw materials to produce glazes of different colors and properties. For example, when producing porcelain, zirconium silicate can be used in combination with titanium dioxide to produce a glaze with high gloss and high hardness.

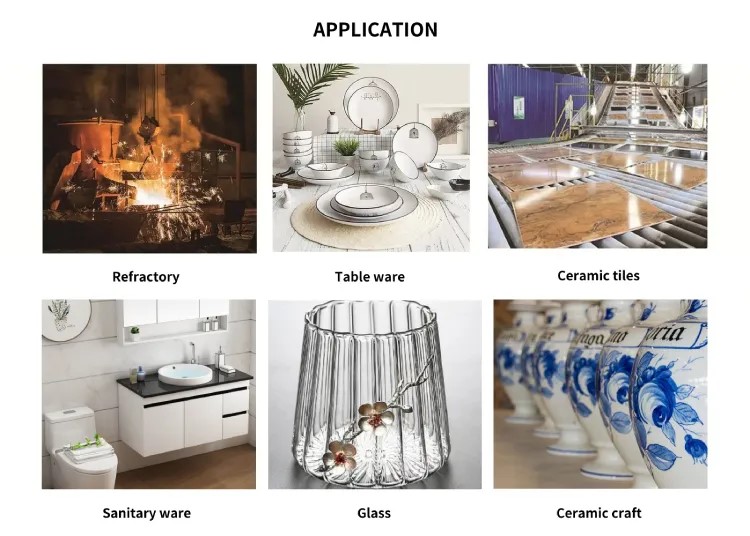

In addition to its application in ceramic production, zirconium silicate can also be used in other fields. For example, it can be used as a refractory material, a packaging material for electronic components, artificial bones and teeth, etc. In these fields, zirconium silicate has played an important role.