Brief Description

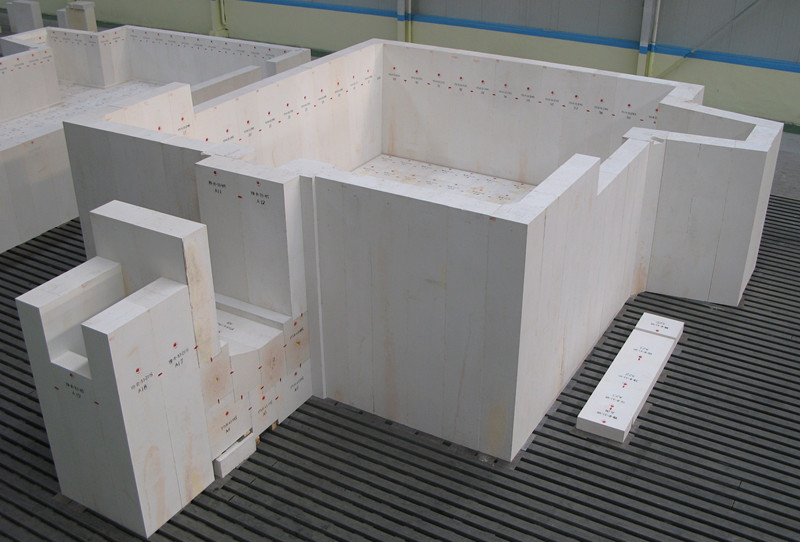

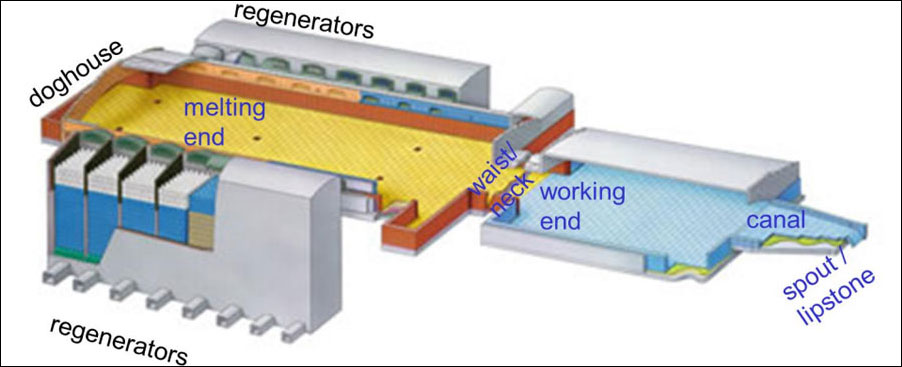

AZS Refractory Bricks & Blocks are produced from alumina powder, zirconia sand and additive. Zirconia content defines their corrosion resistance. AZS Fused Cast Refractories are the most widely used materials in glass melting furnaces, frit kilns and occasionally some foundry plants. AZS Refractory Bricks have low potential for stoning, blistering and exudation of the matrix glass. Therefore, most suitable for use in superstructures of melters, side walls of refiners, paving blocks, and forehearth channel blocks. According to the difference of Al2O3 contents, the AZS bricks usually are classified into the AZS33, AZS36 and AZS41 for your Selection. Contact us for more information and quotation Now.

Melting Technical Requirements

(1) Using the long arc melting process and the secondary voltage is controlled between 320-380. Using high-voltage melting in the initial stage of melting, 380V for secondary voltage , controlling 320V as secondary voltage during the refining, the arc length must reach 50-60mm.

(2) Current selection: At the initial stage of melting, keeping the current between 3500-4000 Ann, and pay attention to the three-phase electrode current Situation at any time, try to maintain the balance, If using strong current for refining, the current control at 4500 Ann.

(3) Oxygen blowing: oxygen is injected step by step, oxygen is blown twice per furnace and the pressure keep 1.4-1.6 megapascals, when the oxygen is blown oxygen lance should be inserted into 1/2 of material liquid depth, and shake slowly to make Oxidation more sufficient.

(4) Melting time: Melting time for per furnace is about 150 minutes, 120 minutes for melting and 30 minutes for refining.

(5) Casting temperature is 1850-1950°C, winter must be above 1950°C.

Technical Specifications

| Item | Fused Cast AZS Brick | |||

| Index | RS-AZS33 | RS-AZS36 | RS-AZS41 | |

| Chemical Composition% |

Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

| ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

| SiO2 | ≤15.00 | ≤13.50 | ≤12.50 | |

| Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

| Volume density g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

| Apparent Porosity % | ≤1.2 | ≤1.0 | ≤1.2 | |

| Cold Crushing Strength Mpa | ≥200 | ≥200 | ≥200 | |

| Exudation Temperature of Glass Phase | ≥1400 | ≥1400 | ≥1410 | |

| Bubble Separation Ratio(1300℃×10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

| Anti-corrosion rate of glass liquid 1500℃×36h (mm/24h)% | ≤1.4 | ≤1.3 | ≤1.2 | |

| Bulk density(g/cm3) | Ordinary casting PT(RN RC N) | ≥3.55 | ≥3.55 | ≥3.70 |

| No shrinking casting ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.75 | ≥3.85 | |

| Tilt casting QX(RO) | ≥3.65 | ≥3.75 | ≥3.90 | |

| No shrinkage castingWS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.80 | ≥3.95 | |

Note: If you have any request for our AZS 33, 36 &41 Refractory Brick, pls email us inquiry@rsrefractorygroup.com for more detailed information and quotation.

Properties

Fused Cast AZS33 Brick is widely used for glass furnace for superstructure, working pool side wall, paving blocks, feeder channels, tank bottom, C-shaped block and doghouse crown,etc.Fused Cast AZS36 Brick is mainly used for sidewall, doghouses, throat, bottom budding, Dam blocks, electric block corners.Fused Cast AZS41 Brick is mainly used for sidewalls, doghouses, bottom budding, Dam blocks, electric block corners.

Characteristics

- High refractoriness under load and High-temperature endurable

- Strong corrosion resistance and High thermal shock resistance

- Good volume stability at high temperature and Low pollution

- High hot crush strength and Good spalling resistance

- Good wear resistance and Thermal conductivity