Brief Introduction

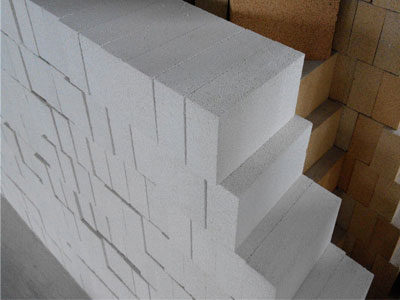

K30/JM30 Insulation Bricks are made from high-purity refractory clays with gradually increasing aluminum oxide content and are carefully saturated with organic filling, which then burns out during the production process, resulting in a homogeneous, controlled porous structure. To achieve required tolerance, all six walls of each brick are mechanically processed.

The total weight of furnace body and walls thickness can be reduced effectively, thermal efficiency and working condition can also be improved,energy consumption can be lowered, produtivity and significant economic results can be achieved.Any interests for our brick, pls email us for more information and quotation:inquiry@rsrefractorygroup.com

Technical Datas

| Brand | JM23/K23 | JM26/K26 | JM28/K28 | JM30/K30 | JM32/K32 | |

| USA Brand | IFB2300 | IFB2600 | IFB2800 | IFB3000 | IFB3200 | |

| Classification Temperature (℃) | 1260 | 1430 | 1540 | 1650 | 1760 | |

| Bulk Density (g/cm3) | 0.55-0.62 | 0.78-0.8 | 0.88 | 1.03 | 1.25 | |

| Cold Crushing Strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

| Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

| Reheating Linear Change (%) | 1230℃ | 1400℃ | 1510℃ | 1620℃ | 1730℃ | |

| CT-30 ℃X 8H | -0.5 | -0.5 | -0.5 | -0.9 | -0.9 | |

| Thermal Expansion 1000℃(%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

| Thermal conductivity(W/m.k) | 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

| 600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

| 800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

| 1000℃ | 0.2 | 0.33 | 0.38 | 0.45 | 0.53 | |

| Al2O3 (%) | 37 | 54 | 64 | 72 | 77 | |

| Fe2O3 (%) | 1 | 0.9 | 0.8 | 0.7 | 0.5 | |

Application

K30/JM30 Insulation Brick should be used as the first layer of a refractory lining or as back insulating layer behind all other refractory layers in furnaces, bakes, fire channels, refining chambers and heat furnaces, regenerators, gas production plants and conduits, intended furnaces, stress-relieving furnaces, reactor chambers and similar high-temperature industrial devices.