Refractory castable is a kind of unshaped refractory material. It is made of refractory aggregates, powders, binders and admixtures through batching and mixing. Depending on the selected aggregates and binders, the castables produced The functions are also different. There are many types of refractory castables, and the corresponding castables can be selected for lining according to the industrial furnace environment.

Through the above introduction, we know that refractory castable is a refractory product used for lining industrial kilns, and refractory cement is used as a binder or refractory powder when making refractory castables, which can make the castables refractory. Quickly combines and promotes coagulation.

When Rongsheng company castable manufacturers produce refractory castables, they usually recommend reasonable refractory castables based on the physical and chemical indicators of refractory castables provided by customers or based on the industrial kiln environment provided by customers and customize the processing to ensure high quality and meet the needs of industrial kilns. Furnace usage requirements.

Note:If you have interest about other refractory castables, welcome to contact us by email: inquiry@rsrefractorygroup.com or whatsapp:+ 0086 13027611300

| Acid Resistant Castable | |

| Item | Index |

| Al2O3 % | ≥40 |

| Acid Resistance % | ≥98.5 |

| Bulk Density (110℃×24h) g/cm3 | ≥2.20 |

| Cold Crushing Strength (110℃×24h) Mpa | ≥30 |

| Cold Crushing Strength (1350℃×24h) Mpa | ≥45 |

Alkali Proof Castable has strong erosion resistance capacity against the alkali gas and clinker and its service life is long. This product is mainly used in linings of kiln hood, decomposing furnace, preheater system, pipeline system and other industrial kiln.

● Al2O3≥45%

● Bulk Density (110℃×24h)≥2.20 g/cm3

● Maximum Service Temperature:1400℃

| Items | High Strength Alkali Proof Castable | ||

| RS-13NL | RS-14N | ||

| Chemical Composition % | Al2O3 | 48 | 45 |

| Bulk Density g/cm 3 | 110℃x24h | 2.2-2.4 | 2.2-24 |

| MOR MPa | 110℃x24h | 7 | 8 |

| 1110℃x3h | 7 | 8 | |

| Cold Crushing Strength MPa | 110℃x24h | 70 | 80 |

| 1110℃x3h | 70 | 80 | |

| Linear Dimensional Change% | 1110℃x3h | ±0.4 | ±0.4 |

| Maximum Service Temperature ℃ | 1300 | 1400 | |

(1) The bulk density is small, and the anticorrosion and penetration of the lining anti-slag should be strong.

(2) Excellent thermal shock resistance, good resistance to rapid cooling or large temperature changes.

(3) High compressive strength and high stability of the high temperature lining.

(4) The use of high temperature can reach 1400-1550 °C

(5) Acid-resistant slag or solution chemical attack.

| Index | High Alumina Castable | |

| Al2o3 % | 65 | |

| Sio2 % | 30 | |

| Cao % | 6 | |

| Bulk density g/cm³ | 110℃,24h | 2.5 |

| 1350℃,24h | 2.6 | |

| Cold bending strength MPA | 110℃,24h | 6 |

| 1350℃,24h | 7.5 | |

| Hot bending strength MPA | 110℃,24h | 45 |

| 1350℃,24h | 60 | |

| 1350 Burning line rate of change | 0.2 | |

| Mixing water consumption % | 10-12% | |

| Operating temperature | 1400 | |

| Index | Corundum Castable Refractory | |

| Model | RS-85 | |

| Chemical Composition(%) |

Al2o3 ≥ | 85 |

| Sio2 ≤ | 6 | |

| Bulk density g/cm³ | 110℃,24h ≥ | 2850 |

| Cold bending strength MPA | 110℃,24h ≥ | 8 |

| 1100℃,3h ≥ | 12 | |

| 1350℃,3h ≥ | 12 | |

| Cold pressure strength MPA | 110℃,24h ≥ | 80 |

| 1100℃,3h ≥ | 95 | |

| 1350℃,3h ≥ | 110 | |

| Burning line rate of change | 1100℃,3h ≥ | -0.3 |

| 1350℃,3h ≥ | -0.5 | |

| Mixing water consumption % | 5-6% | |

| Operating temperature ℃ | 1600 | |

| Items | RS-F16 | RS-F16K | RS-F17 | |

| Al2O3+SiC% | 110℃x24h | 70 | 75 | 8 |

| Bulk Density g/cm 3 | 110℃x24h | 2.6 | 2.7 | 2.8 |

| MOR MPa | 1110℃x3h | 11 | 12 | 13 |

| 110℃x24h | 11 | 12 | 13 | |

| Cold Crushing Strength MPa | 1110℃x3h | 90 | 100 | 110 |

| 1110℃x3h | 90 | 100 | 110 | |

| Linear Dimensional Change % | 110℃x24h | ±0.1 | ±0.1 | ±0.1 |

| 1110℃x3h | ±0.3 | ±0.3 | ±0.3 | |

1. Low cement castables use calcium aluminate cement as the binder, and castables with less than 2.5% CaO content are commonly referred to as low cement castables. Different from traditional castables, low-cement castables, ultra-low-grade aggregated superfines with the same or similar chemical composition as the main material (with a particle size of less than 10 microns) replace most or all of the cement.

2. Application: Low cement castables are mainly used in metallurgy, electric power, nonferrous metals, petrochemical, building materials and other industries.

| Item/Index | RS-M1 | RS-A1 | RS-A2 | |

| Chemical component | 65 | 80 | 90 | |

| Aggregate | Mullite | Corundum | Corundum | |

| Maximum service temperature | 1600 | 1700 | 1800 | |

| Refractorinee | 1750 | 1790 | 1790 | |

| Bulk density | 2.6 | 2.8 | 3 | |

| Linear change after sintered | 1000℃ | -0.2 | -0.2 | -0.2 |

| 1300℃ | ±0.5 | ±0.5 | ±0.5 | |

| Pressure strength after sintered | 110*24h | 30 | 30 | 30 |

| 1000*3h | 50 | 50 | 50 | |

| 1400*3h | 70 | 80 | 80 | |

Rongsheng Refractory Castable Application

We Rongsheng Company are able to supply all kinds of refractory castables (also including other refractory material) that widely are used in Steel Industry, Petrochemical Industry, Metallurgy Industry, Noferrous Industry and Building Industry and suitable for different Furnace/Kiln, such as Glass Kiln, Tundish Furnace, Steel Casting Lable, Cement Kiln, Electric Arc Furnace ,Torpedo Ladle and other various Furnace. If you have interests for our refractory castables and kindly tell which furnace you are using, then our professional engineer will design the drawing with recommended suitable castables in every part of your furnace/ kiln.

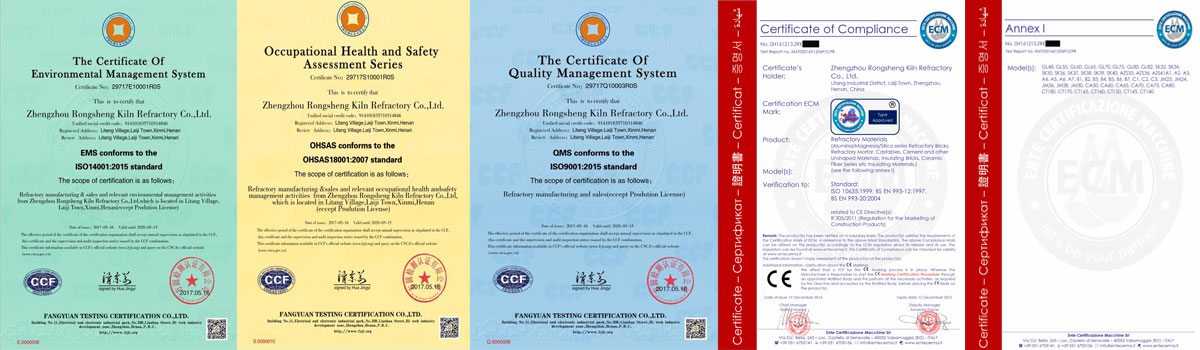

Quality Certification of Rong Sheng Company

Rongsheng Refractory has established complete quality system and conducted quality control through the whole staff and process that from raw materials, production, check and various parts strictly according to ISO9001 standard and with the professional checker at each level to take good product and service as the top goal.We have passed through the certification authority, provide more protect for you. If you also need other Special products certification, please contact us, we are glad to help you make the special approval for you.

Clients Visiting our factory

We rongsheng kiln refractory material group is the leading manufacturer and supplier in China, which have manufacture the refractory products for over 20 years experience, every year, Many clients all over the world come to China for visiting and checking our refractory products and factory to assure the quality and service, if you also have the plan to visit the factory, pls kindly contact us, we will arrange the hotel in advance and pick you up from the airport station or train station, even free invitation letter also will be help for you, if you need.

Why choose Rongsheng as supplier

1. Professional Design Service, if you tell your kiln situation, we can advice you the most suitable refractory brick for every parts of your kiln/Furnace

2. We supply various refractory Bricks and Various fire brick also can be customized by your exact Kiln/furnace and at your request.

3. Professional Manufacturer and supplier, Over 20 years producing experience, over 8000 square meters area.

4. Free Sample Avaiable, Sometimes also with free package and shipping.

5. All of our refractory products meet national standard by strict quality control, Provide various quality certificate.

6. Fast Delivery, by reputed shipping line and professional documents.