According to information from the national environmental protection authorities, in 2016, the amount of hazardous waste produced nationwide exceeded 50 million tons. The harmless treatment of hazardous waste is of great significance to the development of environmental protection. The national “Thirteenth Five-Year Plan Recommendations” puts forward the concept of green development and requires the formation of a sustainable development situation in which waste is diversified, comprehensive, full-scale and law-based, and the waste management is harmless, resource-based, reduced and socialized. At present, hazardous wastes are mainly disposed of through composting, incineration and safe landfill, with incineration being the most common method. The types and characteristics of garbage incinerators used for incineration are as follows:

1. Grate type incinerator

The grate-type incinerator works continuously, and its garbage processing capacity can reach more than 200t/d. There is a grate at the bottom, and the garbage is supplied from the upper hopper. The garbage to be burned is piled on the grate, and combustion air is blown from the lower part of the furnace for drying and direct combustion. Use grate-type incinerators to process garbage. Except for large pieces of garbage, garbage classification and crushing are generally not carried out. The surface temperature of the garbage layer can reach 800°C, and the temperature range of the flue gas is 2800~1000°C. There is only one combustion chamber in the incinerator. chamber, reliable combustion, better utilization of waste heat, good combustion stability, and high burnout rate. The solid waste stays in the furnace for about 1 to 3 hours, and the gas stays in the furnace for about a few seconds; the incinerator is tall and thin, and the volume is relatively large. It is large, has high operation and operation technology, and has a high cost. Moreover, the grate must be resistant to high temperatures, corrosion, and have good mechanical properties, otherwise it will be easily damaged.

2. CAO (Controlled Air Oxidation, controlled air combustion) incineration system

This system is a new type of garbage incinerator with a garbage processing capacity of less than 150t/d. Its characteristics include: the garbage is first thermally oxidized and decomposed, and then burned after gasification. It has good combustion stability and high burnout rate, but the burning speed It is very slow, and the combustion process requires high oxygen and furnace temperature control. If the garbage contains large water content, it cannot burn stably without oil for combustion; there are two combustion chambers in the furnace, and the solid garbage is in the first combustion chamber ( The gas stays in the second combustion chamber (temperature 600~800℃) for about 3~6 hours, and the gas stays in the second combustion chamber (temperature 800~1000℃) for about 1~3s, driven by the pusher.

3. Fluidized bed incinerator

The furnace body of the fluidized bed incinerator is composed of porous distribution plates. A large amount of quartz sand is added to the furnace, the quartz sand is heated to above 600°C, and hot air above 200°C is blown into the bottom of the furnace to boil the hot sand. Get up and put in the garbage again. The garbage boils with the hot sand, and the garbage is quickly dried, set on fire, and burned. The garbage needs to be classified and broken (10~30cm) before entering the furnace, and then suspended and burned in the furnace. This makes the fluidized bed incinerator have high combustion efficiency and high burnout rate, but its garbage processing capacity is only 150t. /d or less; the temperature in the furnace is uniform and the combustion rate is fast. The solid waste stays in the furnace for 1 to 2 hours, and the gas stays in the furnace for about a few seconds.

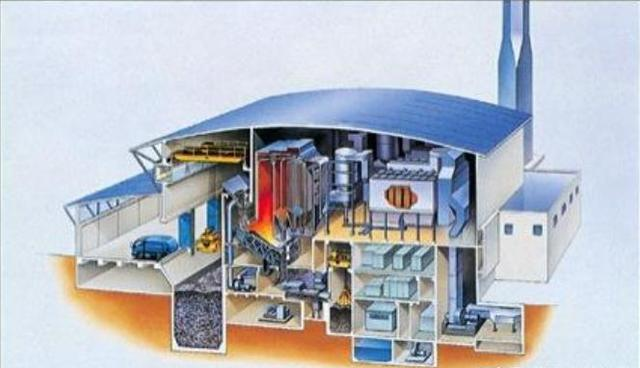

4. Rotary kiln industrial waste incinerator

The rotary kiln incinerator is composed of a rotary kiln, a waste supply device, a secondary combustion furnace, a burner, etc. There is also a grate at the rear for secondary incineration. This type of rotary kiln furnace is suitable for processing large-scale garbage and industrial waste (such as sludge, paint slag, plastics, etc.), and the garbage generally does not need to be classified and broken, and the processing capacity is more than 200t/d; the solid waste stays in the rotary kiln 2~4h, the temperature inside the kiln is about 900°C, and the temperature of the burnout chamber at the rear is 1000~1200°C. After burning, the residual ash particles are small and the burnout rate is high.

It can be seen from the above four types of garbage incinerators that the combustion temperature in the traditional garbage incinerator is generally not high, generally lower than 1000°C, so some combustibles still cannot be fully burned. Some hazardous wastes in the garbage, such as medical waste, The harmful substances cannot be completely treated, which will affect the local soil and water quality and cause secondary pollution to the environment. Moreover, low-temperature incineration will also produce dioxins that are harmful to the natural environment and human body.

In order to fully burn and decompose garbage and achieve zero emission of dioxin, many high-tech technologies have been applied to solid waste treatment since the 1980s, such as ultrasonic method, gasification and melting technology, garbage-derived fuel method, and photochemical oxidation. technology etc.