Brief Introduction

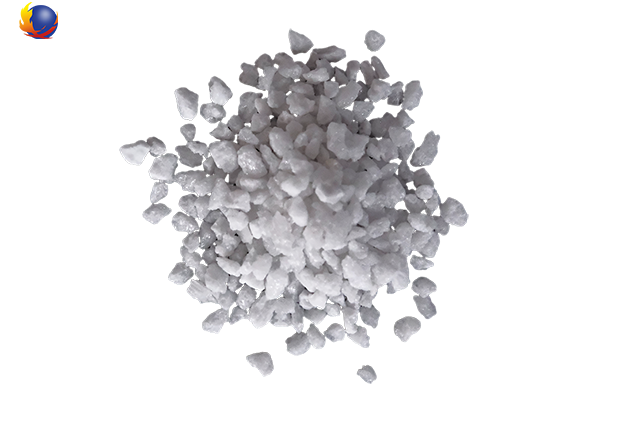

White Fused Alumina (WFA): Aluminum oxide (Al2O3) has a content of over 99% and contains small amounts of iron oxide, silicon oxide, and other components, appearing white.White Fused Alumina uses first grade low sodium industrial alumina as raw material, which is melted at 2250°C in a high-temperature electric arc furnace.

Its texture is dense, high hardness, and the particles form sharp corners. It is suitable for manufacturing ceramics, grinding tools, as well as grinding, polishing, sandblasting, precision casting, etc. It can also be used to manufacture advanced refractory materials.

Technical Data

| ltem | Unit | Grain | Fine Powder |

| Al₂O₃ | % | ≥99.50 | ≥99.30 |

| Na₂0 | % | ≤0.30 | ≤0.35 |

| SiO₂ | % | ≤0.05 | ≤0.06 |

| Fe₂O₃ | % | ≤0.05 | ≤0.05 |

| Refractoriness | ℃ | ≥1850 | ≥1850 |

| Moh’s Hardness | / | ≥10 | ≥10 |

| True Density | g/cm³ | ≥3.9 | ≥3.9 |

| Bulk Density | g/cm³ | ≥3.6 | ≥3.6 |

Mode:Section sand, particle size, fine powder and micro powder

Size:8-5、5-3、3-1、1-0MM;14、16、20、24、30、36、46、60、80、100、120、150、180mesh;200、240、280、320mesh;400、600、800、1000、1500、2000、2500mesh;More

specifications and sizes can be customized.

Application

White Fused Alumina uses first grade low sodium industrial alumina as raw material,which is melted at 2250℃ in a high-temperature electric arc furnace.It has the advantages of low sodium content,high purity,high temperature resistance,low porosity,large bulk density,good thermal stability,and good acid and alkali corrosion resistance.

White Fused Alumina is the main raw material for the production of amorphous and shaped refractory materials,and it is the main raw material for the production of amorphous refractory materials such as large ladle castable,medium and high grade iron hook castable,prefabricated parts,and various corundum products such as corundum bricks and high temperature industrial kiln linings.