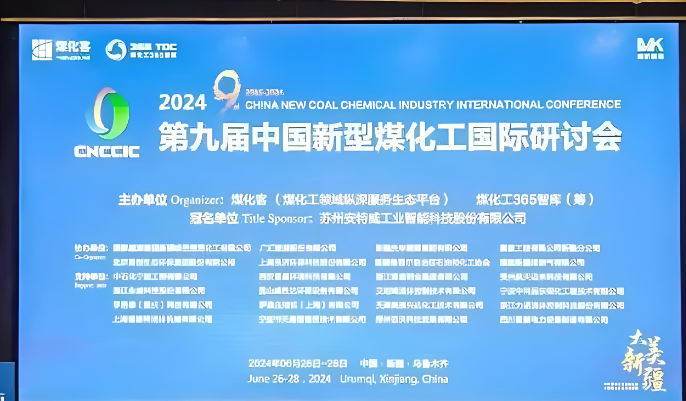

On June 26, the 9th China New Coal Chemical Industry International Seminar, hosted by Coal Chemical Customer (coal chemical industry in-depth service ecological platform) and Coal Chemical Industry 365 Think Tank (in preparation), was held at Jinjiang International Hotel in Urumqi. Rongsheng Kiln Engineering, as a company focusing on the full life cycle solutions for thermal kiln linings, was invited to participate and discuss the path of green, low-carbon and sustainable development with the guests. !

This conference adheres to the characteristics of professionalism, authority, internationality and high standards, and focuses on inviting well-known academicians and experts and scholars in the field of coal chemical industry at home and abroad, industry authorities, planning and research institutions, major coal chemical bases (parks), project construction, high-tech and equipment manufacturing, engineering design, construction, scientific research institutes, universities, dual-carbon research and investment and financing institutions to participate in the conference to exchange ideas and discuss cooperation, conduct in-depth discussions on the hot and difficult issues in the current development of the coal chemical industry, and promote the green, low-carbon and high-quality development of the coal chemical industry.

Rongsheng Kiln Engineering is a wholly-owned subsidiary of Henan Rongsheng Technology Group that focuses on the general contracting of thermal kiln lining projects. It is committed to the full life cycle service of research and development, configuration, production and manufacturing, engineering construction, and technical services for refractory materials for thermal kilns. The company has advanced optimization concepts in various furnace structures such as circulating fluidized bed boilers, gasifiers, boiling furnaces, and waste incinerators. It has accumulated rich experience in kiln construction, design, improvement, construction, furnace drying and insulation, and has formed a service chain that runs through the entire life cycle of thermal kiln linings. With superb construction technology, high-quality construction standards and sincere and thoughtful services, it has won high praise and good reputation from many builders and owners.

As a pioneer in the innovation of thermal kiln lining technology, the company relies on the strong R&D capabilities of Henan Province High Thermal Shock Resistant Refractory Engineering Technology Research Center and Zhengzhou City High Temperature Refractory and Circulating Fluidized Bed Boiler Refractory Engineering Technology Research Center, and continues to make breakthroughs. It not only has multiple qualifications such as first-class professional contracting for waterproof, anti-corrosion and insulation engineering, second-class general contracting for metallurgical engineering construction, and second-class general contracting for environmental protection engineering construction, but also has products that have passed CE, SGS, TUV, INTERTEK, BV and other international authoritative certifications, and its quality and performance are recognized worldwide. Combined with our profound experience in kiln construction and management, we implement precise policies for various projects, and ensure the excellent execution of each project with scientific management and exquisite craftsmanship.

For Rongsheng Kiln Engineering, this event is not only a showcase for the company’s superb technical strength and rich project experience, but also a bridge for in-depth dialogue and cooperation with experts and scholars inside and outside the industry. Looking to the future, Rongsheng Kiln Engineering closely follows the grand pace of the national carbon neutrality strategy, insists on intensive research and development of thermal kiln lining technology, continuously injects innovative vitality, and vows to continuously promote the coal chemical industry towards a green and low-carbon process in the name of science and technology, and write a glorious chapter of sustainable development.