Brief Description of Zirconium Silicate:

Zirconium silicate is a non-toxic, odorless white or off-white powder. The raw material is natural high-purity zircon sand concentrate, which is then processed through superfine grinding, iron removal, titanium processing, and surface modification treatment.

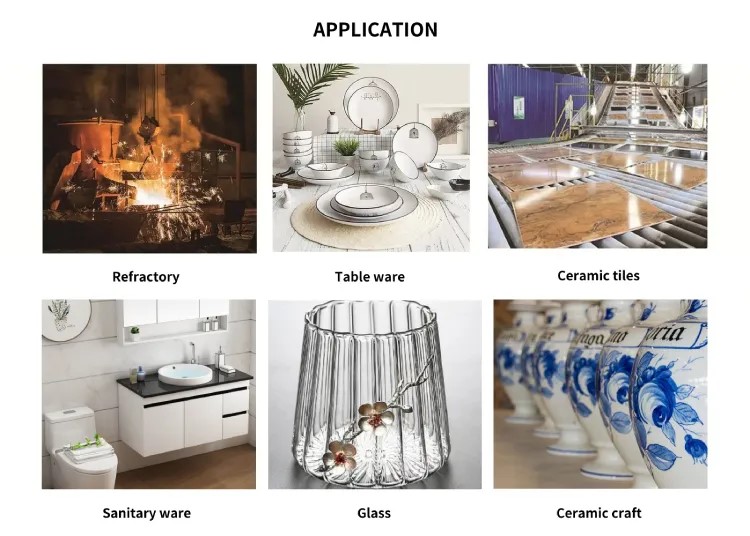

Zirconium silicate has a high refractive index of 1.93-2.01 and stable chemical performance. It is a high quality and low price opacifier for opacification. It is widely used in the production of various building ceramics, sanitary ceramics, daily ceramics and first-class handicraft ceramics. Zirconium silicate has been widely used in ceramic production because of its good chemical stability, so it is not affected by the burning atmosphere of ceramic, and can improve the binding performance of ceramic glaze significantly and improve the hardness of ceramic glaze. Zirconium silicate has been further applied in the production of color picture tube, emulsified glass and enamel glaze in the glass industry.

Zirconium Silicate Parameters

- Physical properties

| Specific Gravity | 4.69 |

| Melting Point | 2500°C |

| Refractive Index | 1.97 |

| Mohs Hardness | 7.5 |

| Thermal Expansion Coefficient | 4.2*10-6 |

| Apprearance | White or off white powder |

- Chemical properties

| Item | RS65 | RS64.5 | RS63.5 |

| ZrO2+HfO2 | 65.0 min | 64.5 min | 63.5 min |

| Fe2O3 | 0. 06 max | 0. 08 max | 0. 12 max |

| Ti02 | 0.10 max | 0.12 max | 0.18 max |

- Product standard

| Type | Average mesh | Application |

| RS-1.0 | D50≤1.0um | High-grade sanitary porcelain

High-grade daily-use porcelain High-grade crystal brick |

| RS-1.2 | D50≤1.2um | |

| RS-1.5 | D50≤1.5um | Middle and low class sanitation porcelain,external and internal brick, archaized brick, engobe, body, etc. |

| RS-2.0 | D50≤2.0um |

Zirconium Silicate Powder

1)Refractory materials and products, glass kiln zirconium ramming material, castable, spray coating, etc. (zirconium silicate melting point is very high :2500℃)

2)TV industry color kinescope, glass industry emulsified glass, enamel glaze production

3)Plastics industry: used as fillers requiring stability, heat resistance and chemical erosion resistance

Related Refratory Brick